" You’ll Never Have A Product Or Price Advantage Again. They Can Be Easily Duplicated, But A Strong Customer Service Culture Can’t Be Copied."

- Jerry Fritz

We provide a wide range of technical services delivered by an experienced team of professionals to continuously provide the customer solution with a focus on quality and excellence which includes,

General Rules Of Electrical Installation Design

1. Connection to the MV utility distribution network

2. Connection to the LV utility distribution network

3. LV Distribution

4. LV switchgear

5. Load

Conditions That Can Make More Frequent Maintenance Necessary Are:

• High humidity and ambient temperatures • Corrosive atmosphere • Excessive dirt and dust • High repetitive duty • Frequent interruption of faults • Older equipment • History on preceding inspections • Lack of periodical maintenance

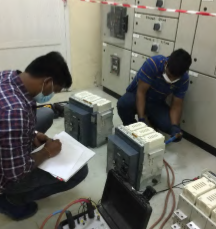

Preventive maintenance consists of carrying out, at predetermined intervals or according to prescribed criteria, checks intended to reduce the probability of a failure or deterioration in the operation of a system.

When switchgear malfunctions, the consequences are often catastrophic. Damage to the switchgear itself can be extremely expensive, but that pales in comparison to corollary damage and the potential hazards to people. That’s why implementing an effective switchgear testing, inspection, and maintenance program is essential.

IEC60364-6 requires initial and periodic verifications of electrical installations. The electrical switchboard and all its equipment continue to age whether they operate or not. This aging process is due mainly to environmental influences and operating conditions.

Raptors provide the complete electrical testing, maintenance, and engineering services you need to extend the life of your switchgear. Our comprehensive services are in line with National Fire Protection Association (NFPA) recommendations and designed to keep your switchgear operational for as long as possible.

There Are Two Types Of Preventive Maintenance:

Periodic maintenance

For each type of product, maintenance recommendations are laid out by the product manufacturer or described in IS / IEC Standards. These verification procedures, intended to maintain systems or their subassemblies in correct operating conditions over the targeted service life, must be carried out according to the time intervals stipulated in this document.

Conditional maintenance

To a certain extent, conditional maintenance operations are a means to reduce (but not eliminate) the recommended periodic maintenance operations (thus limited to the strict minimum) that require an annual shutdown of the installation.

These operations are launched when programmed alarms indicate that a predefined threshold has been reached. (Number of operation) durability, aging indicators

For instance, Electronic trip units in the power circuit breaker can propose such functions. Conditional maintenance is the means to optimize installation maintenance.

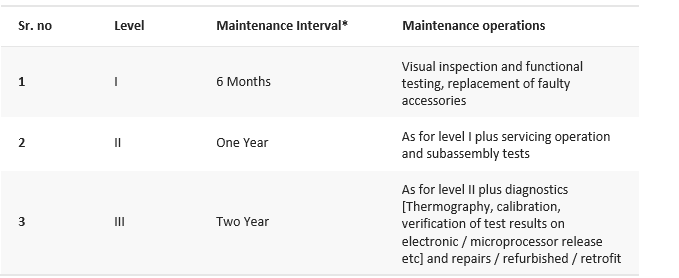

There are three recommended maintenance levels. The table below indicates maintenance operations and their intervals according to the level:

Benefits over replacing complete switchboards include:

Some Of The Benefits Of Retrofit Switchgear Include:

Benefits Over Replacing Complete Switchboards Include:

A typical retrofit involves the replacement of old circuit breakers and switches by modern circuit breakers which offer better efficiency and protection. This option is particularly attractive to organizations with a concentrated age profile of installed equipment and where asset replacement budgets are limited. This eliminates re-cabling, civil work, relocation of transformer or bus duct. Moreover, a retrofit of circuit boards with protection equipment can result in an increase of the life of equipments.

Refurbishment restores the equipment to its original condition and performance specification. It can actually enhance ratings or performance, dependent on the equipment involved.

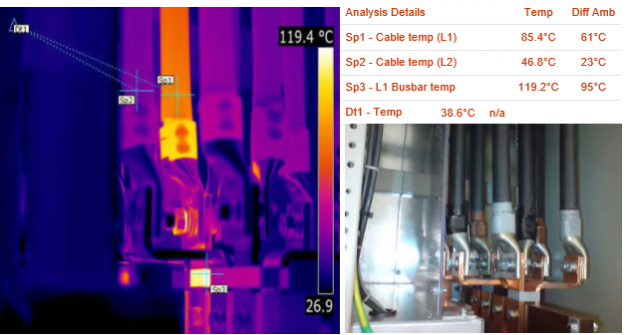

Thermographic Testing of Electrical Equipment

Thermography is a non-destructive test method that may be used to detect poor connections, unbalanced loads, deteriorated insulation, or other potential problems in energized electrical components. These problems may lead to excess power use, increased maintenance costs, or catastrophic equipment failure resulting in unscheduled service interruptions, equipment damage, or other problems.

Thermography, also called infrared inspection, is based upon the sensing of heat emitted from the surface of an object in the form of infrared radiation. Test instruments are used to detect and convert the infrared radiation into either a temperature value or a thermal image, which can be used to assess the thermal condition of the object at the time of measurement. An infrared camera is one common type of infrared thermal imaging device.

Energized electrical systems generate heat because of electrical resistance. The amount of heat generated is related to the amount of current flowing through the system and the resistance of the individual system components and connections within the system. As components deteriorate, their resistance increases, causing a localized increase in heat. Similarly, a poorly made connection will have higher resistance than a well-made connection, along with a higher temperature profile. Thermography may be used to detect these temperature differences.

The National Fire Protection Association (NFPA) estimates that ten percent of the fires occurring in manufacturing properties are related to electrical system failures, such as failure of electrical insulation, terminals, and related components. Additionally, failures can cause employees to be exposed to live electrical circuits, making them susceptible to serious injury or death from electrocution. By detecting high-resistance connections and repairing them, the likelihood of a breakdown of the electrical wires and related components should be reduced. Other advantages to detecting and repairing these faults are the cost savings from energy conservation and lower outage and repair costs. High resistance in circuits causes an increase in current flow. When the current flow is increased, the resulting power consumption will increase. Further, high current draw can cause critical electrical circuit components, such as fuses, circuit breakers, and transformers, to fail prematurely. These failures result in higher maintenance and repair costs, and resultant business interruptions.

While all properties can benefit from a Thermographic scan, those with high power consumption, multiple branch circuits, and distribution subsystems, or heavy equipment have the greatest need. Businesses with high electrical demands should have a Thermographic scan performed at least annually on critical systems, such as Air Circuit Breaker, Power Control Centre, Switchgears, and transformers. We will recommend corrective and preventive action based on the scan results.

We undertake the drilling and installation of earthing boreholes for grounding or lightning protection purposes. Installation of earthing rod, earth pit chamber, copper tape, earth cable, and air terminal is also undertaken.

One of the leading companies in the Installation, commissioning, testing, and Maintenance of Diesel power generators in Qatar. We owe our success to our hardworking, highly skilled, and committed employees. Experience and commitment enable us to provide a professional and efficient service to all customers regardless of whether a single standby generator or multiple set baseload paralleling or synchronizing system. We offer a variety of maintenance contracts that cater to each customer’s needs. Not only do we offer diverse packages of service and maintenance contracts, but we also tailor to each customer’s needs by developing on-demand customized contracts.

The purpose of most generator sets is to provide a reliable source of power to your facility or commercial operation during an emergency situation when power from the grid is suddenly lost or is not available in your environment. In the event of a power failure, one should have peace of mind that their backup power source will kick into action at a moment’s notice. But what happens when the power goes out and Generator Set does not function as expected? The result can often be costly and sometimes catastrophic. This is precisely the reason generator load bank testing is an essential piece of a comprehensive preventative generator maintenance plan, which you should ideally have conducted on your Generator Set each year. Load bank testing helps to ensure that your generator will be fully dependable and operational, as well as completely capable of the highest possible load it may be required to handle at any critical point in time.

A generator load bank test involves an examination and assessment of a Generator Set each year. It verifies that all primary components of the generator set are in proper working condition. The equipment used to conduct a load bank test produces artificial loads on the generator by bringing the engine to an appropriate operating temperature and pressure level. This is especially important for standby and emergency generator sets that do not run very often and/or may not be exposed to carrying heavy loads on a frequent basis. The general rule is – if your generator is not exposed to higher than 30% of its rated kW load then you should be considering a load test. A load bank test ensures that your generator will run properly when it's needed so that you can fully depend on it during an emergency situation. The key to a proper load bank test is that it tests your generator at its full kilowatt (kW) output rating. Because many generators do not regularly operate at their full kW rating, it’s especially important that you verify your generator can actually produce the highest possible horsepower that may be required – while at the same time maintaining adequate temperature and pressure levels that will allow it to run as long as necessary.

Benefits Of Load Bank Testing

There are multiple reasons gensets should undergo a load bank test on an annual basis, including the following:

Our Typical Load Bank Reports Include The Following:

All electrical devices work properly without any failure if the input power is well within set limits of electrical properties. So Power Quality Study determines the health of the electrical to load ends. Without the proper power, an electrical device (or load) may malfunction, fail prematurely or not operate at all. There are many ways in which electric power can be of poor quality and many more causes of such poor quality power. The quality of electrical power may be described as a set of values of parameters, such as:

Continuity of service

Variation in voltage magnitude.

Transient voltages and currents

Harmonic

All these unwanted parameters can increase in power consumption, heating of equipment’s and wiring, malfunctioning or even damage.

We use Three Phase Power Quality Analyser for:

Identify various types of harmonics, Harmonic study

The calculation for Total Harmonic Distortion.

Power Factor Study

Identify ways to improve power factors.

Energy consumption study

Review of Single line diagram.

Review of the connected load.

Variation of current and Voltages between phases.

Measurement of input current and voltage.

Comparison of the unbalancing with the prescribed limits.

Installation, commissioning, testing, and maintenance of fire protection and detection systems for all classes of buildings, industrial, commercial and residential in accordance with NFPA codes and standards. All reports are to QCDD requirements.

Fire Alarm Systems

Fire Detection Systems

Firefighting Equipment

Aerosol System

Kitchen Hood Fire Suppression

Smoke and Natural Ventilation

Indirect Systems for Electrical Cabinets

Gas Suppression System

FM200 & Deluge System

Datacenter functional testing is a process whereby the performance of your data center’s physical infrastructure – most often power and cooling is verified against your user requirements. Many data centers have some experience with this testing as it is common to see a ‘load bank’ test performed on a UPS when it is purchased. This test attaches live load (via load banks) to the UPS to verify that the unit can support its full kVA capacity. Many other tests, like a battery rundown test, are typically performed at this time. In some cases, the load banks are placed on the data center floor to test perimeter CRAC units.

The challenge for data centers today is that their data center facility is built to last 25 years but the technology inside that facility is refreshed every two to three. Functional testing performed when the facility was originally built doesn’t give you verification that a change in technology and computing density can be supported by the power and cooling infrastructure currently in your data center. This is most notable in existing data centers that are working to deploy (through virtualization) higher density workloads – IT teams worry that their data center cooling systems cannot support this change in per rack density.

Using data center functional testing to verify the performance of power and cooling infrastructure is a critical step for any organization moving to higher density workloads in their existing facility.

1. More than 500 HAC230-6RM Load banks in stock (up to 3.3 MW)

2. Full Heat Load Test

3. To test a mechanical system

4. To test the electrical system

5. Effect of change over from supply A to B

6. To test UPS, Generator, and utility supply

7. Environmental conditions

8. Engineering & reporting of :

-Temperature / Humidity data logging

-Thermal imaging of DBs and PDUs

-Airflow measurement and visualization.

-Power Quality Analysis

-Integrated System Testing

Raptors Trading & Contracting has been established in February 2015 and it currently represents multiple reputable international brands. Our traditional business model is based on trading and contracting in the electrical engineering sector.

Quick Links

Contact Us

© Copyright 2024 Raptors Qatar. Proudly Powered by oxi-smart.net

WhatsApp us